- This topic is empty.

-

AuthorPosts

-

2025-05-28 at 7:18 pm #6571

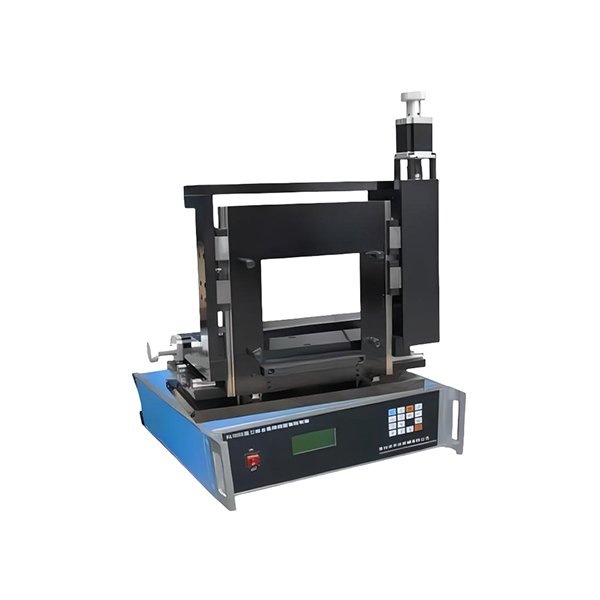

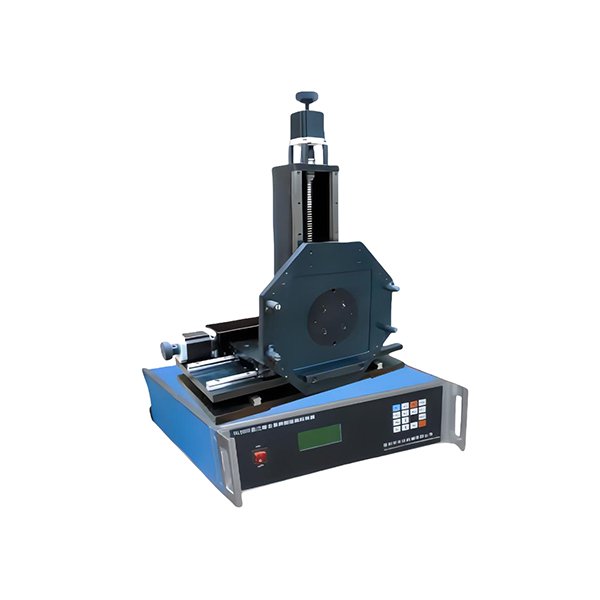

As the demand for ultra-precise holographic patterns and anti-counterfeiting technologies grows, the 3D Automatic Hologram Master X-Y Table has emerged as a cornerstone in advanced holography production. This sophisticated piece of equipment enables the accurate positioning and movement required for mastering 3D holographic designs on substrates. But what exactly makes this system so crucial?

What Is a 3D Automatic Hologram Master X-Y Table?

At its core, a 3D Automatic Hologram Master X-Y Table is a high-precision motion platform used in the fabrication of holographic images. It provides bidirectional movement along the X and Y axes, enabling controlled exposure of laser beams or electron beams on holographic plates. This positioning is essential when generating high-resolution holograms with multi-dimensional depth and intricate patterns.

It is commonly used in:

Security printing (currency, passports, ID cards)

Brand protection (product authentication labels)

Decorative holography (packaging, gift wrap, etc.)

Optical component production (lenses, gratings)

Key Components of the System

To understand the mechanics, let’s break down the major components that make the system work:

1. Precision Linear Stages (X and Y Axes)

The core of the X-Y Table comprises two motorized linear stages. These stages are typically driven by:

Linear motors

Stepper motors

Piezoelectric actuators (for ultra-fine motion)

High-grade ball screws or air bearings are often used to ensure smooth, backlash-free movement. The mechanical assembly must offer sub-micron resolution, which is vital for detailed hologram structuring.

2. Motion Controller and Software Integration

The brain of the system lies in its motion controller. This component ensures synchronized, programmable movement based on the hologram design file. It integrates with specialized software that allows:

Design mapping

Speed control

Dwell time programming

Path optimization (to reduce vibration and time)

Advanced systems may even include real-time feedback loops from sensors to correct any deviations dynamically.

3. Vibration Isolation Platform

Any external vibration—be it from building infrastructure or nearby equipment—can distort the hologram. Thus, most high-end tables are mounted on vibration-isolated platforms, either passive (pneumatic) or active (electronic stabilization), ensuring ultra-stable positioning.

4. Z-Axis (Optional) for Focus Control

Some systems also feature a Z-axis control mechanism to adjust the focal depth, especially important when working with thick substrates or creating 3D effects through multi-layer recording.

The Working Principle of the

The hologram creation process usually involves directing a laser or e-beam onto a photoresist-coated substrate. The X-Y table moves the substrate in tiny increments based on a pre-programmed design.

Here’s how it typically works:

1. Design Input: The user loads the holographic pattern into the control software.

2. Calibration: The system aligns the beam source and the table to a zero-reference point.

3. Exposure Phase: As the beam remains stationary or moves in sync, the table shifts precisely beneath it, exposing the desired pattern.

4. Feedback Adjustment: High-resolution encoders track movement and adjust in real-time to maintain accuracy.

5. Completion: After the exposure process, the substrate is developed to reveal the master hologram.

This process demands tight control over parameters like speed, position accuracy, repeatability, and environmental stability—all of which are addressed through the mechanical and software components of the system.

Core Benefits of the 3D Automatic Hologram Master X-Y Table

The 3D Automatic Hologram Master X-Y Table offers a host of advantages for manufacturers and designers of holographic content:

1. Unmatched Precision: With positioning resolutions in the nanometer range, intricate holographic patterns can be created reliably.

2. Automation: Automated patterning allows for repeatability and mass production.

3. Design Flexibility: The programmable nature of the table supports both raster and vector-based designs.

4. Human Error: Automatic operation eliminates inconsistencies caused by manual processes.

5. Scalability: The same platform can be adapted for different substrates and design complexities.

Industry Use Cases

Let’s take a look at how various industries utilize this system:

Government agencies use it for secure document production with tamper-proof holograms.

Luxury brands incorporate complex holograms on packaging as part of anti-counterfeiting strategies.

Optics manufacturers utilize it in the creation of holographic lenses and gratings with precise geometrical structures.

Tech companies explore it in AR/VR applications where wavefront shaping and 3D imaging are essential.

Choosing the Right System: What to Look For

When selecting a 3D Automatic Hologram Master X-Y Table, several factors should be considered:

1. Motion Accuracy: How fine is the resolution, and how accurate is the repeatability?

2. Software Capabilities: Does the system support advanced pattern design and real-time corrections?

3. Substrate Size Compatibility: Can it accommodate the size of your holographic plates?

4. Throughput Speed: Is it suitable for your production volume?

5. Maintenance & Support: Are spare parts and tech support readily available?

Conclusion

The 3D Automatic Hologram Master X-Y Table is more than just a positioning platform—it’s the heartbeat of modern holographic patterning. Its mechanical precision, software intelligence, and robust build make it an indispensable tool in the race toward higher security, finer detail, and smarter production.

For anyone in the holography, optics, or security printing industries, understanding the mechanics of this system isn't just beneficial—it's essential.

A Comprehensive Guide to the 3D Automatic Hologram Master X-Y Table: Features and Applications

http://www.zhhologram.com

Wuxi Zhongheng New Anti Counterfeiting Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.