- This topic is empty.

-

AuthorPosts

-

2026-02-02 at 5:25 pm #9228

Seamless carbon steel welded pipe is a strong tube. It does not have any joints. Many industries use this pipe. It works well under high pressure. It can handle tough jobs. The oil and gas sector uses it the most. This sector uses more than half of all these pipes. Power generation also needs these pipes. Automotive and construction use them too. These pipes help things work safely and smoothly.

-

The global carbon steel pipe market will grow. It will go from USD 15.7 billion in 2023 to USD 23.5 billion by 2032.

-

Oil and gas, construction, and automotive make this growth happen.

Key Takeaways

-

Seamless carbon steel pipes are tough and dependable. They work well for high-pressure jobs in oil and gas. These pipes do not have weld seams. This means there are fewer weak spots. It helps them handle tough conditions better. Picking the right steel grade is very important. It makes sure the pipe works well and lasts long. Seamless pipes can cost more at first. But they last longer and need less fixing. This can save money later. People use seamless carbon steel pipes in oil and gas pipelines. They are also used in building projects and power systems.

Seamless Carbon Steel Pipe Overview

Key Features

Seamless carbon steel pipe is special because it has no seams. It is made by piercing a solid steel billet. This makes the pipe smooth and even. The pipe is strong and lasts a long time. No seams means no weak spots. The pipe can handle high pressure and tough jobs.

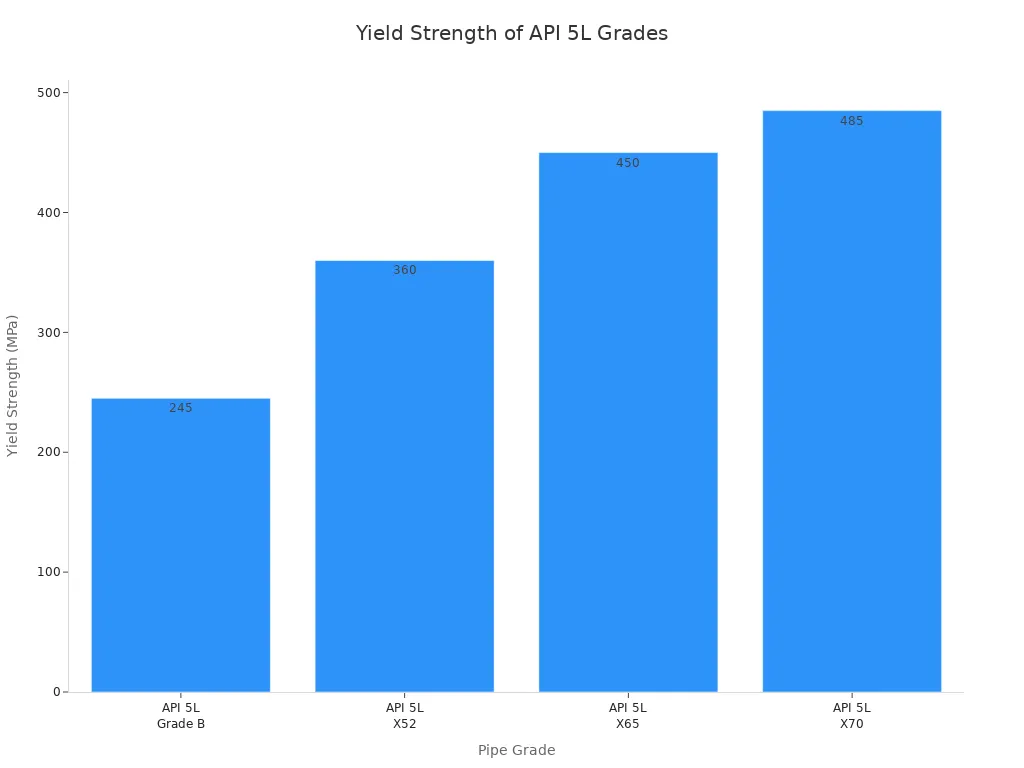

The strength of seamless carbon steel pipes changes with each grade. The table below shows some grades and their strength:

Grade

Yield Strength (MPa)

Tensile Strength (MPa)

Elongation (%)

API 5L Grade B

245

415

10 – 25

API 5L X52

360

460 – 630

10 – 25

API 5L X65

450

535 – 760

10 – 25

API 5L X70

>485

570 – 760

10 – 25

Seamless carbon steel pipe has carbon, manganese, phosphorus, and sulfur. Carbon ranges from 0.02% to 2.1%. Low carbon steel has up to 0.25% carbon. Medium carbon steel has 0.25% to 0.6%. High carbon steel has 0.6% to 1.0%. Manganese is between 0.30% and 1.50%. Phosphorus and sulfur are less than 0.050%. These elements make the pipe stronger and tougher.

Seamless carbon steel pipes have a smooth inside. This helps fluids move easily. It lowers friction and turbulence. The pipe does not rust easily. No weld seams means fewer weak spots. These pipes work well in places with high pressure and heat.

Comparison with Welded Pipes

Seamless carbon steel pipes are different from welded pipes. Welded pipes are made by rolling and welding steel strips. This makes a seam along the pipe. The seam can be weak, especially under high pressure.

The table below shows the main differences:

AuthorPostsViewing 1 post (of 1 total)- You must be logged in to reply to this topic.

-