- This topic is empty.

-

AuthorPosts

-

2025-07-16 at 3:31 pm #6997

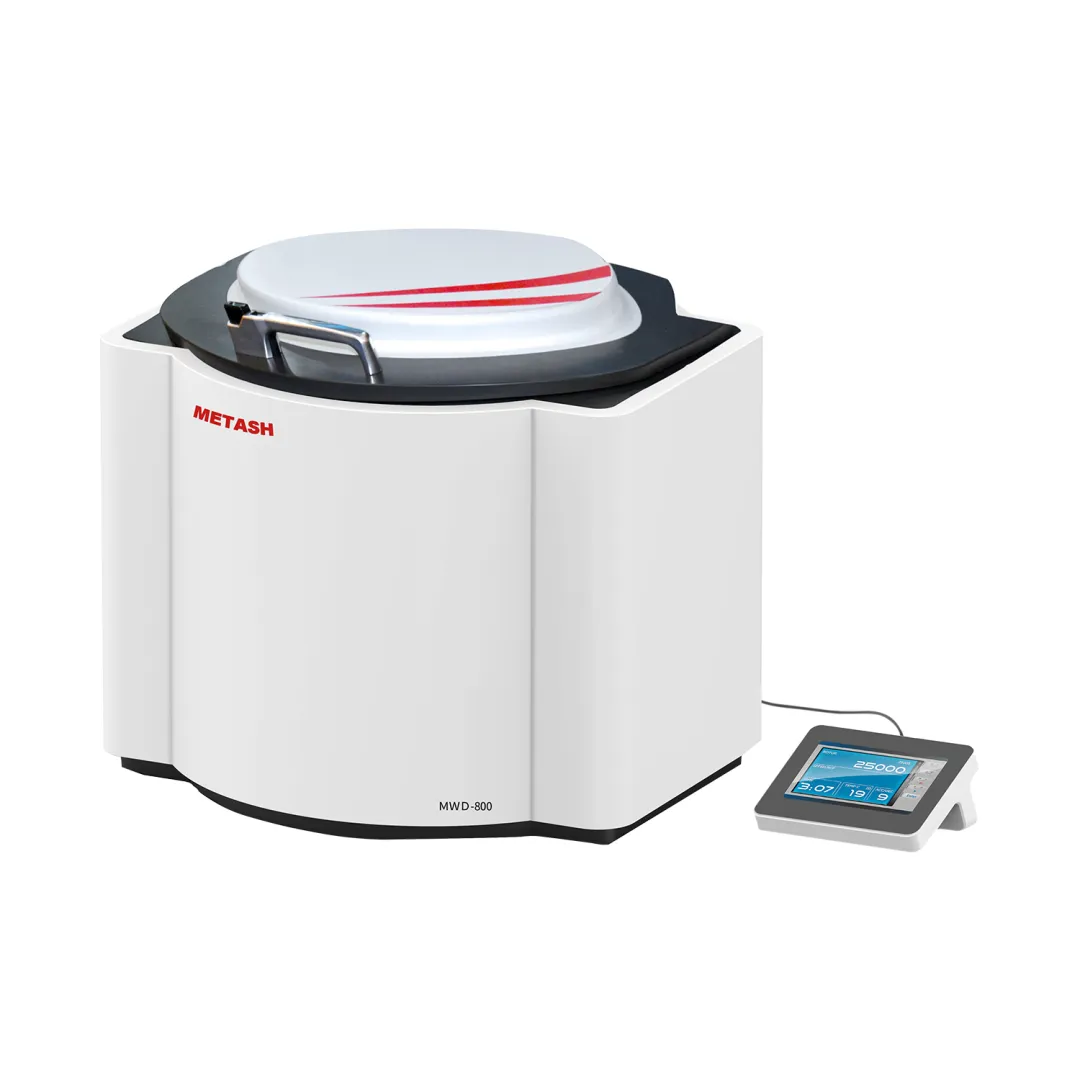

In the fields of geological exploration, mineral resource assessment, and environmental monitoring, the digestion of geological samples is a crucial step in analytical testing. Traditional digestion methods such as hot plate digestion and high-pressure vessel digestion have long been used, but they come with several drawbacks, including long processing times, high reagent consumption, and the potential loss of elements. The advent of microwave digestion technology has significantly mitigated these issues. In this blog post, METASH will share the application of closed smart microwave digestion system in geological samples digestion, which has become an indispensable equipment in modern laboratories due to its fast, efficient and precise characteristics.

Rapid Digestion: Drastically Reducing Experimental Cycles

Geological samples often contain refractory components such as silicates, sulfides, and oxides, which can take several hours or even longer to digest using traditional methods. The smart microwave digestion system leverages microwave energy to directly act on the sample molecules, causing them to decompose rapidly under high-temperature and high-pressure conditions. This not only accelerates the experimental process and allows for quicker data acquisition but also enhances the efficiency of geological exploration and mineral resource development.

Moreover, the rapid digestion capability of the smart microwave digestion system is further enhanced by its batch processing ability. For instance, the microwave digestion system from METASH is equipped with multi-channel reaction vessels that can handle multiple samples simultaneously. This significantly boosts the throughput of the laboratory, which is particularly important for large-scale geological surveys and mineral prospecting. It can notably reduce labor costs and improve overall work efficiency.

Enhanced Precision: Minimizing Element Loss and Ensuring Data Accuracy

The analysis of trace elements in geological samples requires extremely precise control of the digestion process. Traditional digestion methods, due to uneven temperature distribution or localized overheating, may lead to the loss of volatile elements such as mercury, arsenic, and selenium, thereby affecting the accuracy of the final analytical results.

The smart microwave digestion system from METASH achieves precise control over temperature, pressure, and digestion time, ensuring that samples are uniformly heated in a closed environment. This effectively reduces the volatilization and adsorption losses of elements.

– Uniform Heating and Minimizing Element Volatilization and Adsorption:

– The system employs three-dimensional microwave output technology, which matches the harmonic power-frequency heating to achieve more uniform heating.

– The 360° continuous rotating turntable reduces the temperature difference between reaction vessels.

– Real-time Monitoring of Temperature and Pressure:

– A non-contact mid-infrared temperature measurement system is used to continuously detect, control, and display the temperature and temperature profile inside the digestion vessel.

– A non-contact multi-fiber pressure control system continuously monitors, controls, and displays the pressure and pressure profile within the digestion vessel.

Environmental and Energy Efficiency: Reducing Reagent Consumption and Waste Discharge

Traditional digestion methods typically require large amounts of strong acids such as nitric acid, hydrofluoric acid, and perchloric acid. This not only increases experimental costs but also generates a significant amount of hazardous waste, posing potential threats to the environment.

The closed system of the smart microwave digestion system from METASH significantly reduces the amount of reagents needed, usually requiring only one-third to one-half of the amount used in traditional methods to complete the digestion process.

Safety and Durability

– High-strength Safety Enclosure:

– The entire enclosure of the system is made from carbon fiber-reinforced polymer materials.

– The inner vessel of the digestion system is made from imported TFM, which prevents liquid from adhering to the walls and is resistant to strong acid corrosion.

– The outer vessel is made from imported PEEK mixed with glass fibers, which can withstand high temperatures and pressures without deformation.

– Self-recovering Dual Pressure Relief:

– It ensures both safety and high recovery rates.

The smart microwave digestion system from METASH assists researchers in more accurately assessing the economic value of ore deposits. Additionally, in petroleum geological research, the microwave digestion of samples such as shale and sedimentary rocks provides a reliable basis for hydrocarbon analysis and elemental geochemical studies.

In conclusion, the application of the smart microwave digestion system in the digestion of geological samples has brought about significant improvements in efficiency, precision, and environmental sustainability. It is undoubtedly a valuable asset for modern laboratories engaged in geological research and analysis.

http://www.metashcorp.com

METASH -

AuthorPosts

- You must be logged in to reply to this topic.