- This topic is empty.

-

AuthorPosts

-

2025-01-16 at 10:25 am #5769

When considering the purchase of a diesel engine for water pump, it's crucial to evaluate various cost factors to ensure that the investment aligns with your budget and operational needs. Here's a detailed breakdown of the key cost components you should consider:

Initial Purchase Cost

The upfront cost of the diesel engine is a primary consideration. Prices can vary significantly based on the engine's specifications:

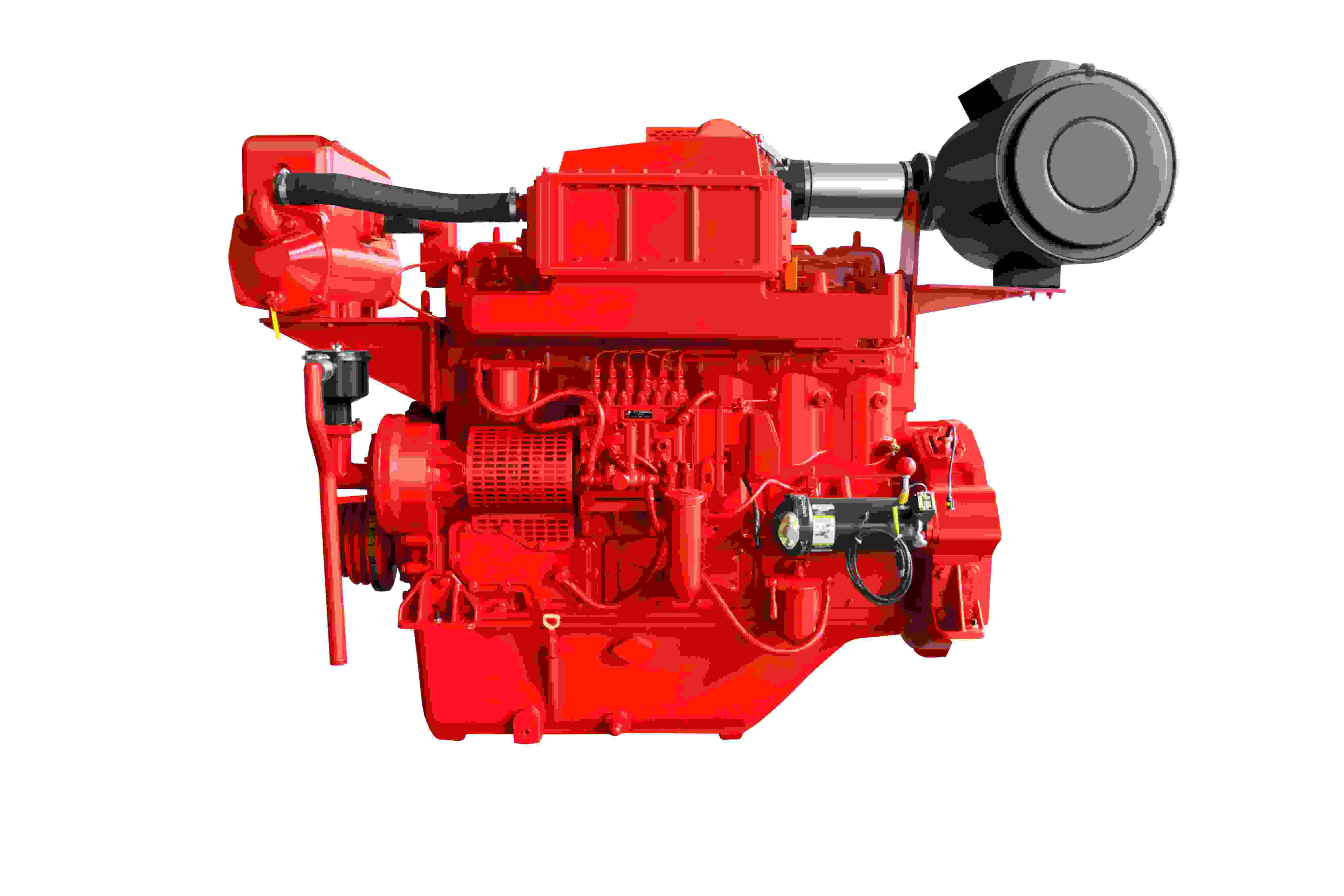

Power Output: Engines with higher horsepower (HP) or kilowatts (KW) will generally cost more due to their increased capacity to handle demanding workloads.

Engine Type: Diesel engines are known for their durability and efficiency, but the specific design and technology used can influence the price.

Brand and Manufacturer: Reputable brands often command higher prices due to their track record for reliability and performance, but they may also offer longer service life and lower maintenance costs. Wuxi Power Engineering Co., Ltd., with its extensive experience and expertise in developing and manufacturing high-quality diesel engines, offers a range of reliable and efficient options for water pump applications. Our engines are known for their durability, performance, and compliance with industry standards, making them a suitable choice for various industrial and commercial needs.

Operational Costs

Fuel Efficiency: The cost of diesel fuel is a significant ongoing expense. Engines with better fuel efficiency will have lower operational costs over time, even if they have a higher initial purchase price.

Maintenance and Repairs: Diesel engines require regular maintenance to ensure optimal performance and longevity. This includes oil changes, filter replacements, and periodic inspections. The cost of maintenance can vary based on the engine's complexity and the availability of service providers.

Installation and Setup Costs

Labour Costs: The installation process can be labour-intensive, especially if the engine needs to be integrated into an existing system or if additional infrastructure is required.

Auxiliary Equipment: You may need to purchase additional components such as fuel storage tanks, exhaust systems, and mounting equipment, which can add to the overall cost.

Environmental and Regulatory Costs

Emissions Controls: Modern diesel engines often come with advanced emissions control technologies to comply with environmental regulations. These features can increase the initial cost but are necessary for legal compliance.

Permits and Licenses: Depending on your location and the intended use of the water pump, you may need to obtain permits or licenses, which can involve additional fees.

Additional Features and Options

Enhanced Features: Some engines offer additional features such as digital control systems, self-priming capabilities, or remote monitoring options. While these features can improve the engine's functionality and ease of use, they also add to the cost.

Customization: If you require a diesel engine with specific modifications to meet unique operational requirements, customization can increase the price.

http://www.wandipower.com

Wuxi Power Engineering Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.