- This topic is empty.

-

AuthorPosts

-

2025-06-05 at 6:39 pm #6621

Crafted with ingenuity, this multi-layer co extruded board of ABS, HIPS, GPPS, PP, and PE reshapes industry standards with outstanding performance! The combination of rigidity and flexibility is extraordinary, with ABS high strength and impact resistance, HIPS easy to process, GPPS high transparency, PP high rigidity, lightweight and durable, and PE low temperature resistance, flexibility and stability; Fearless of corrosion, able to cope with harsh environments with ease, and resistant to damage from acid, alkali, and hot water invasion;

Combining aesthetics and creativity, various textures such as glossy, matte, embossed, etc. can be customized at will, ea sily lighting up visual charm;

Fulfilling our green commitment, our recyclable design seamlessly integrates environmental protection with resource utilization, providing a high-quality board solution that combines performance, aesthetics, and environmental friendliness!

Application of JWELL' s intelligent technology in improving product quality and efficiency

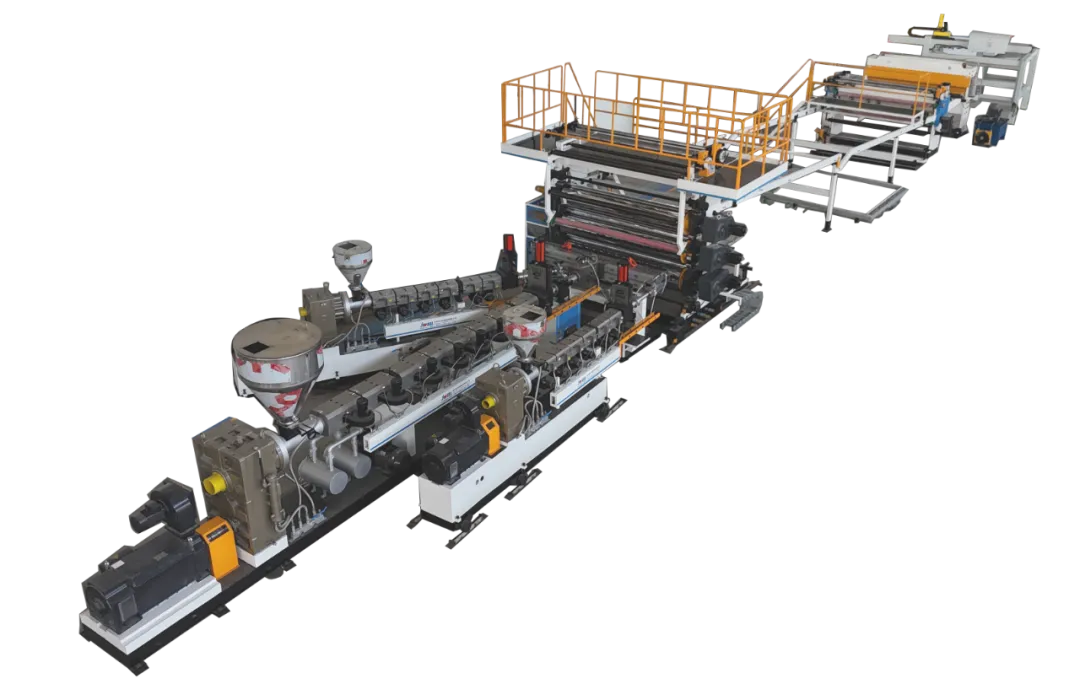

1.Composition of production line

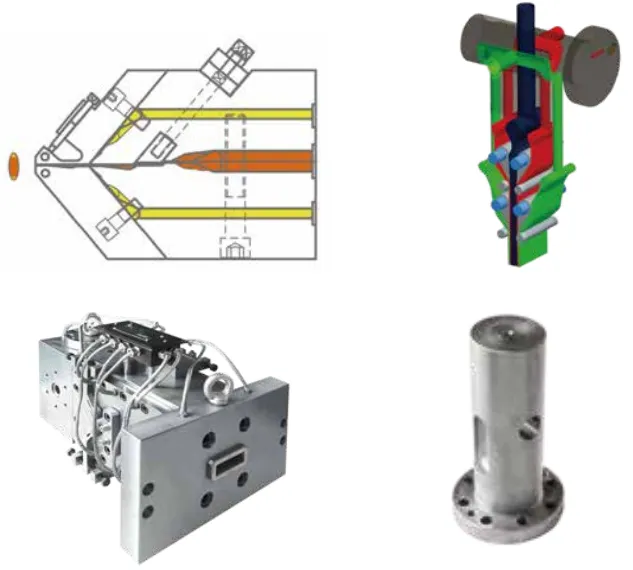

Extrusion System

Composed of multiple single screw extruders, special screws are designed for different materials, combined with a PLC temperature control system to ensure plasticization and stable output. Equipped with a hydraulic screen changing device, the screen can be changed without stopping the machine.

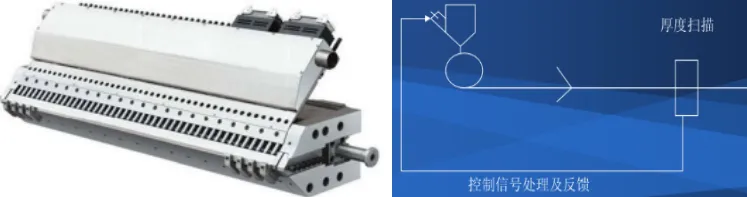

Mold

Adopting a hanger style sheet mold, it can be equipped with a melt metering pump to achieve quantitative and pressure conveying of materials, ensuring stable extrusion of melt and uniform thickness of products.

Molding system

Equipped with a vertical/oblique three roll calender, equipped with a roller temperature controller and high-precision gap adjustment sensor, and equipped with an emergency stop function; The cooling bracket is equipped with high-precision alumina roller conveyor, and can be equipped with cutting and trimming devices as needed.

Traction and cutting system

The traction machine uses rubber rollers to ensure the stability of the board, and the speed is synchronized with the three rollers; The horizontal cutting machine adopts cylinder clamping and follow-up cutting, equipped with alloy saw blades and dust suction devices. According to requirements, the robotic arm can be configured online for automatic stacking.

Control system

Adopting PLC control system, equipped with human-machine interactive touch screen, it can store process parameters, achieve automated operation, monitoring and fault diagnosis.

2.Raw material weighing and blending system

It can record the relevant data of each ingredient, such as the type of material, weight, and mixing time, which is convenient for quality traceability and production management, and helps enterprises achieve refined production and quality control.

3.High-precision thickness intelligent control feedback system

Real-time thickness monitoring and automatic feedback adjustment system enable intelligent control of the production process, enhancing product quality and production efficiency.

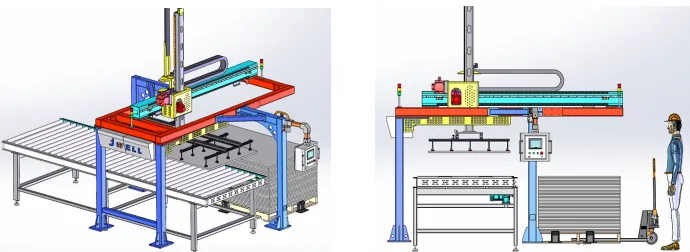

4.Intelligent robotic arm for online extraction and palletizing

Technological process:

Origin of robotic arm – gripping signal – robotic arm descending – vacuuming gripping – robotic arm ascending – Enter the palletizing area – Robot descends – Release the board – Robot returns to the designated point.

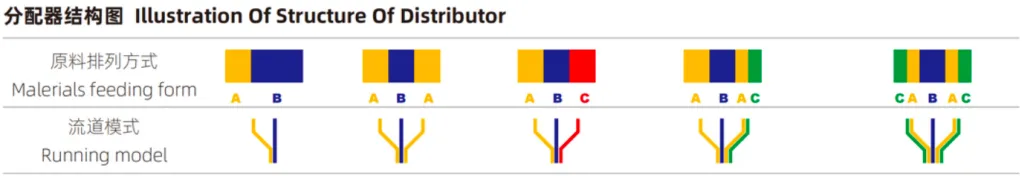

Applicable product structure types

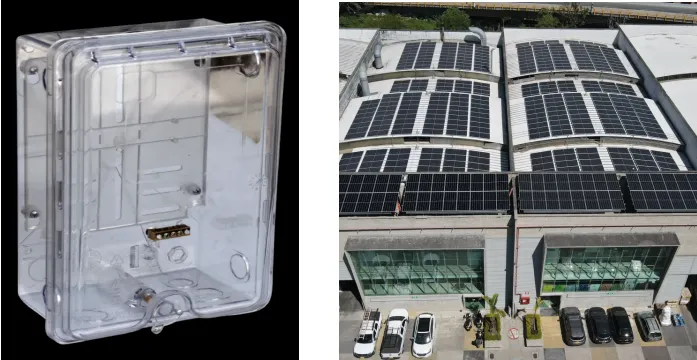

lllustration Of structure of Distributor

Note: The allocation ratio and materials are determined based on the actual needs of the customer

Main parameters of machine

Width:1220— 2500mm

Thickness:0.2—6.0mm

Capacity:400—1000Kg/h

Application

✓ Lighting light guide plates and diffusion plates are used in ultra-thin lightboxes and LED flat panel display lights.

✓ EV charging stations and electric vehicle charging stations, etc.

✓ Refrigerator industry: HIPS multi-layer co extruded sheet has outstanding resistance to CFC-11 and is often used for components such as refrigerator door sills, inner liners, drawers, water trays, etc.

✓ Sanitary products, such as bathtubs, shower rooms, steam rooms, washbasins, etc. can be made into various shapes and specifications of sanitary products using their good processing and physical properties.

✓ Automotive Interior: Can be used for car roofs, instrument panels, seat backrests, door panels, etc., providing lightweight and high-strength interior materials for cars.

Material performance analysis

Comparison of PP,PE,ABS,HIPS,GPPS material

Project

PP

PE

ABS

HIPS

GPPS

Density (g/cm³)

0.89-0.91

0.91-0.96

1.04-1.06

1.03-1.06

1.04-1.07

Heat Resistance

100-120

80-100

90-110

70-85

70-90

Transparency

semi-transparent

Semi/opaque

not transparent

not transparent

high transparency

Impact Resistance

medium

high

extremely high

medium

low

Rigid

high

low

high

medium

extremely high

Chemical Resistance

acid and alkali resistant

acid and alkali resistant

general

poor

bad

Insulation

excellent

excellent

good

good

very good

Cost

low

lowest

higher

low

low

Service Life

10-30 years

10-50 years

15-30 years

10-20 years

10-20 years

Note: The synthesized material can perfectly meet the needs of customers in the field of charging stations.

Jwell Guarantee · Trustworthy

As the world's leading manufacturer of polymer material extrusion equipment, Suzhou Jwell Machinery insists on customer-centricity and technology-centricity, and is committed to creating every intelligent production line with global competitiveness. The multi-layer co extrusion board equipment is a strategic achievement of our deep understanding of the development trends of household appliances, automobiles, construction, and new energy industries, as well as the integration of material science and intelligent manufacturing.

Welcome to inquire about customized solutions, make an appointment for a trial machine visit, and create an intelligent manufacturing future together!

Suzhou Jwell Machinery Co., Ltd.

http://www.jwellplas.com

JWELL -

AuthorPosts

- You must be logged in to reply to this topic.