- This topic is empty.

-

AuthorPosts

-

2025-09-22 at 6:21 pm #7719

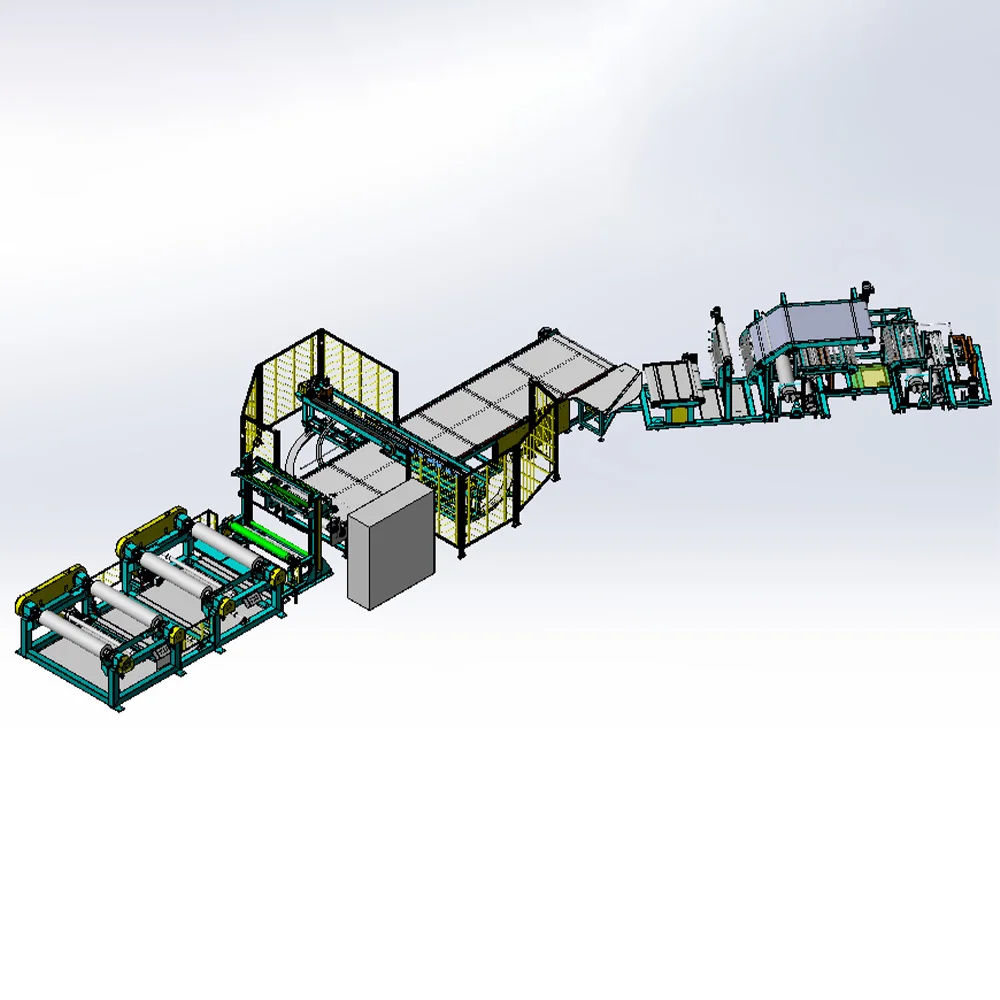

In today’s tire and rubber industry, efficiency and precision are the defining factors of success. The automatic ply cutting machine represents a transformative advancement, offering manufacturers the ability to streamline complex processes while maintaining high standards of quality. Designed with state-of-the-art control systems that meet international standards, this equipment ensures consistency, reliability, and minimal downtime during production. In this blog post, as a high performance bias cutting machine factory, SONIWELL will share the advantages of automatic ply cutting machine for sale, its features, etc.

Core Advantages of Automatic Ply Cutting Machine

The integration of automation into ply cutting processes has introduced several unique benefits that go beyond conventional equipment:

-

Uninterrupted Operations – With a fully automatic working mode, downtime is minimized, allowing for continuous and stable production.

-

Flexible Let-Off Stations – The selectable dual-station configuration (rotatory or front-and-rear) enhances adaptability, while the manual/automatic splicing function streamlines workflows.

-

Intelligent Positioning Control – A dual-servo drive structure in the main conveyor belt stripping device ensures accurate alignment and precise material feeding.

Intelligent Splicing with Vision and Robotics

One of the most remarkable features of this modern ply cutter is its integration of vision-guided robotics into the splicing process. Unlike conventional splicing, which often relies heavily on manual alignment, the machine employs a combination of camera-based detection and robotic precision.

This results in:

-

Superior splice quality with consistent results across high-volume runs.

-

Enhanced production efficiency, reducing waste and improving material utilization.

-

Reliable accuracy, with splicing misalignment deviation controlled within ±1mm.

Advanced Rolling Operation and Angle Control

The automatic rolling system embedded in this ply cutting solution further increases production capacity. Once the ply is cut and spliced, the rolling mechanism completes the process automatically, requiring operator intervention only when changing the cart.

Key aspects include:

-

Automated angle rotation, ensuring rolls are consistently aligned.

-

Smooth handling of materials, eliminating the inconsistencies of manual rolling.

-

Reduced labor intensity, enabling operators to focus on higher-level monitoring rather than repetitive manual tasks.

Equipment Performance Parameters

The machine has been engineered with a balance between speed and accuracy, making it an ideal choice for high-demand industrial applications.

Technical Specifications:

-

Cutting Angle: 0–67°, 90°

-

Cut Width: Maximum 1450mm

-

Cutting Speed: Up to 18 cuts per minute (at 0°, width 460mm)

-

Ply Thickness: 0.6–1.6mm

-

Splicing Efficiency: Up to 13 splices per minute (at 450mm hypotenuse length)

These parameters highlight the machine’s ability to deliver consistent output, even in demanding, high-speed production environments.

Unmatched Equipment Accuracy

For industries such as tire manufacturing, accuracy is non-negotiable. The automatic ply cutting equipment ensures extremely tight tolerances:

-

Cutting Angle Deviation: ±1°

-

Cut Width Deviation: ±1mm

-

Splicing Width Deviation: ±1mm

-

Splicing Misalignment Deviation: ±1mm

Such precision not only improves product quality but also reduces material waste and ensures compliance with strict industrial standards.

Seamless Integration into Production Lines

Beyond its technical strengths, the computerized ply cutting machine has been designed for easy integration into existing production lines. With fully automated synchronization of cutting, splicing, and rolling, manufacturers can achieve:

-

Optimized workflow with fewer manual interventions.

-

Scalable production, supporting both small-batch and large-scale operations.

-

Improved workplace safety, as automation reduces manual handling of heavy materials.

Sustainability and Cost Efficiency in Ply Processing

Modern manufacturers face increasing pressure to balance productivity with sustainability. By reducing errors, minimizing rework, and improving material efficiency, the automated ply cutter contributes directly to cost savings and waste reduction. Its precision-driven design ensures that fewer resources are consumed while output remains consistently high.

Conclusion

The automatic ply cutting machine is more than just an upgrade to traditional cutting equipment—it represents a new industry benchmark for precision, efficiency, and automation. From vision-guided splicing to servo-driven positioning, every feature is designed to maximize productivity while ensuring exceptional product quality. For manufacturers aiming to stay competitive in a fast-evolving market, investing in this advanced solution is not just an option—it’s a necessity.

http://www.soniwellgroup.com

SONIWELL -

-

AuthorPosts

- You must be logged in to reply to this topic.