- This topic is empty.

-

AuthorPosts

-

2025-08-20 at 6:39 pm #7347

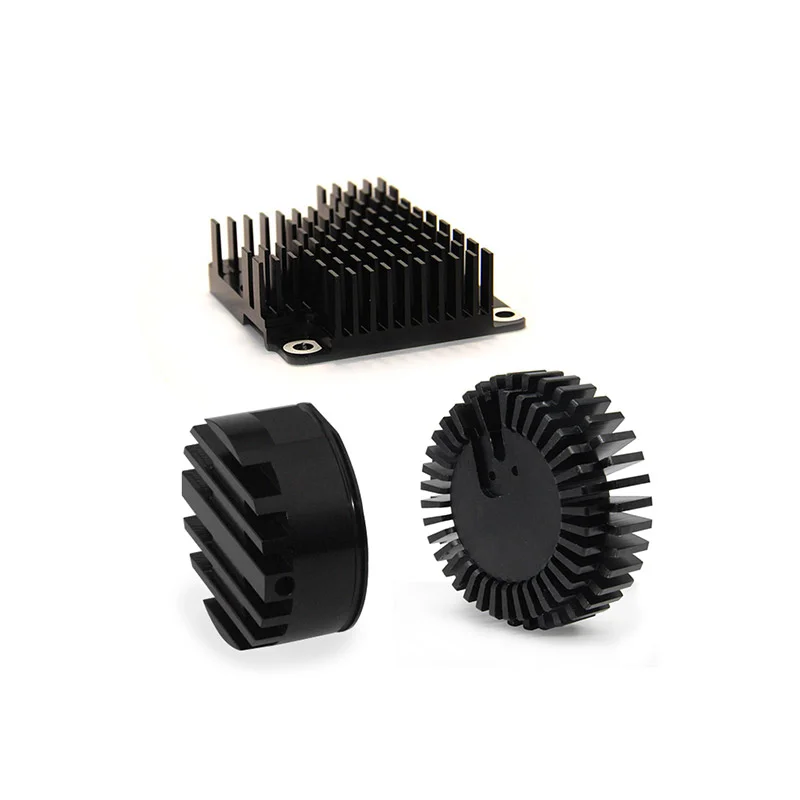

Aluminum extrusion heatsinks play a critical role in thermal management across various electronic and industrial applications. Among the diverse types available, black anodized custom aluminum heatsinks stand out due to their enhanced durability, thermal performance, and visual appeal. The surface treatment of these components is not merely aesthetic—it profoundly impacts performance, longevity, and compatibility with specific applications. In this blog post, Vibo, a professional high precision parts machining service provider, will share the surface treatment of custom black aluminum extrusion heatsink for sale.

Importance of Surface Treatment in Aluminum Heatsinks

Aluminum, while naturally corrosion-resistant due to its oxide layer, can benefit significantly from engineered surface treatments. These enhancements improve the metal's mechanical and thermal properties, increase corrosion resistance, and enable better integration into assemblies. Surface treatments are especially crucial for custom heatsinks, which are often tailored to unique operational environments.

Anodizing: The Preferred Method for Black Heatsinks

Anodizing is the most common surface treatment for aluminum extrusion heatsinks. This electrochemical process increases the natural oxide layer on the aluminum surface, making it thicker, harder, and more durable.

Key Benefits of Anodizing for Heatsinks:

-

Improved Corrosion Resistance: The anodized layer protects the aluminum from oxidation and chemical attacks, especially in moist or chemically aggressive environments.

-

Enhanced Surface Hardness: Anodizing increases the surface hardness of the aluminum, providing better wear resistance and mechanical protection.

-

Coloring Capability: Anodizing allows for the introduction of dyes—black being the most commonly chosen color for heatsinks due to its thermal emissivity advantages.

-

Electrical Insulation: The anodized layer acts as an electrical insulator, reducing the risk of short circuits in electronic applications.

Why Black Anodizing?

The choice of black anodizing for heatsinks is not merely for aesthetics. Black surfaces have higher emissivity, which means they can radiate heat more efficiently. In passive cooling applications, where convection and radiation are the primary modes of heat dissipation, black anodized finishes offer measurable performance advantages.

Thermal Radiation Efficiency:

Black anodized heatsinks emit thermal radiation more effectively than bare or clear anodized ones, improving overall heat dissipation—especially critical in fanless or constrained environments.Industrial Aesthetic Appeal:

Beyond function, black anodizing provides a sleek and professional look that blends well with modern electronic assemblies, making it a preferred choice for consumer electronics and industrial systems alike.

Alternative Surface Treatments

While anodizing remains the gold standard, other surface treatment methods are sometimes applied depending on the application, cost constraints, or performance requirements.

1. Powder Coating

Powder coating involves applying a dry powder to the surface of the heatsink, which is then cured under heat to form a solid coating. Although less common for heatsinks due to its lower thermal conductivity compared to anodizing, it is used in applications where aesthetic uniformity or thicker coatings are desired.

Pros:

-

Excellent mechanical protection

-

Wide range of color and finish options

-

Good corrosion resistance

Cons:

-

Reduced thermal conductivity

-

Thicker layer may reduce heat dissipation efficiency

2. Electrophoretic Deposition (EPD)

EPD, or e-coating, is another method used for applying a uniform, thin protective coating to aluminum surfaces. It offers good corrosion resistance and a smooth finish.

Use Cases:

Often applied where precise coating thickness and high corrosion resistance are required, such as in automotive or aerospace applications.3. Chemical Conversion Coating (Alodine/Chromate Conversion)

This process creates a thin film over the aluminum surface without significantly affecting thermal performance. It is usually employed as a pre-treatment or when minimal interference with heat dissipation is needed.

Advantages:

-

Low thermal resistance

-

Provides a conductive surface

-

Suitable for applications where electrical grounding is essential

Surface Finish Considerations in Custom Extrusion Design

When designing a custom aluminum extrusion heatsink, surface treatment should be factored into both the geometry and functional parameters. Several aspects must be considered:

-

Coating Thickness: This affects tolerances and the final dimensions of the heatsink. Precision applications must account for added layer thickness.

-

Surface Roughness: The smoother the surface, the less particulate buildup over time, which can improve airflow and reduce thermal resistance.

-

Adhesion and Compatibility: Surface treatments must be compatible with adhesives, mounting components, or electronic modules that interface with the heatsink.

Post-Treatment Quality Assurance

Once the surface treatment is applied, rigorous quality control is essential to ensure consistent performance across production batches. Common inspections include:

-

Thickness Measurement: Using eddy current or micrometer-based tools to ensure uniform coating.

-

Adhesion Testing: Especially for powder-coated or dyed anodized surfaces, adhesion must be verified using tape or crosshatch tests.

-

Corrosion Testing: Salt spray or humidity chamber tests simulate harsh environments to evaluate coating durability.

Environmental and Regulatory Considerations

Modern manufacturing demands sustainability and regulatory compliance. Black anodizing, being a relatively eco-friendly process, avoids the use of volatile organic compounds (VOCs) and heavy metals. Furthermore, RoHS (Restriction of Hazardous Substances) compliance is essential for electronic components, making anodized aluminum a favorable material.

Conclusion

The surface treatment of custom black aluminum extrusion heatsinks is far more than an aesthetic choice. It is a critical aspect of the design and engineering process that directly influences thermal performance, longevity, and environmental resilience. Among the available options, black anodizing stands out due to its exceptional emissivity, corrosion resistance, and visual appeal. However, alternative treatments like powder coating, EPD, and chemical conversion coatings also offer unique advantages in specific scenarios. For optimal results, a collaborative approach involving design engineers, surface treatment experts, and quality assurance professionals is essential to ensure that the final heatsink meets all performance, durability, and compliance requirements.

-

-

AuthorPosts

- You must be logged in to reply to this topic.