- This topic is empty.

-

AuthorPosts

-

2025-08-20 at 6:38 pm #7345

PE pipes are widely used in municipal water supply and drainage, gas transmission, agricultural irrigation, and industrial pipelines due to their corrosion resistance, lightweight design, environmental friendliness, and long service life. To meet market demands, our company provide high-speed, high-efficiency, intelligent, and energy-saving PE pipe extrusion lines, empowering our clients to enhance their competitiveness.

Core Advantages:

✔ High-speed & High-efficiency: Advanced extrusion technology increases production speed by 30%, significantly boosting output capacity.

✔ Intelligent Control: Automated systems ensure precise parameter adjustments for consistent pipe dimensions and superior quality.

✔ Energy-saving : Optimized energy consumption design reduces production costs and embraces green manufacturing trends.

Pipe Extrusion Line—Component parts

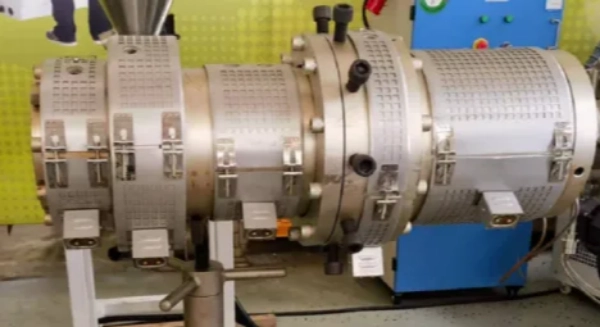

Extruder

Spiral groove IKV system, water-cooled feeding section.

Barrel: 38CrMoAlA, nitriding treatment, professional trapezoidal groove design, 4D feeding section forced water cooling, the temperature of the spiral groove surface sleeve can be adjusted, thus ensuring the stability and reliability of the output in the high- speed extrusion process.

Screw: 38CrMoAlA, nitriding treatment, new double separation type screw, reinforced mixing section screw structure specifically suitable for processing domestic PE100 and imported materials, a new high-efficiency screw with different pitch and mixing unit.

mported brand reducer high torque, low noise, hardened gear surface, long life reducer, forced circulation lubrication.

Insulation cotton air-cooled ceramic heating ring.

Equipped with meter weight system, it is more stable and energy-efficient during operation.

Molds&Calibrators

Main parts are made of high quality mold steel

The surface of the runner is nitrided or polished by electroplating

Uniform material dispersion, low shear heat, easy adjustment of the mouth mold

Suitable for different pressure levels of the mouth mold and core mold coordination

Water film type cooling structure

Vacuum Tank

Low vacuum shaping pipe products after forming residual stress elimination sufficient

Powerful spraying cooling Uniform cooling

Optimize the design of cooling pipelines and vacuum systems

Adopts 304 stainless steel, beautiful appearance and smooth line shape

ABB inverter vacuum automatic control device ABB

Large filter system, convenient for timely cleaning of pipeline blockages

Haul-off Unit

Belt type traction

Servo motor and servo control system, high precision, stable traction speed

Long traction effective length, large rubber block, high adhesion force and high torque

The upper traction limit adjustment device can effectively prevent the tube from being flattened when traction thin- walled tube

Cutter

Specially designed alloy blade and hydraulic feed method

PLC control synchronous operation

16-32mm diameter pipe by fly cutter and integration construction

Plastic Machinery Fully Integrated Automation + Internet Of Things Control System Solutions

Based on the MES system platform, the information communication platform of workshop production management is realized and move toward the intelligent direction.

http://www.jwellplas.com

Jwell -

AuthorPosts

- You must be logged in to reply to this topic.