- This topic is empty.

-

AuthorPosts

-

2025-04-17 at 5:46 pm #6285

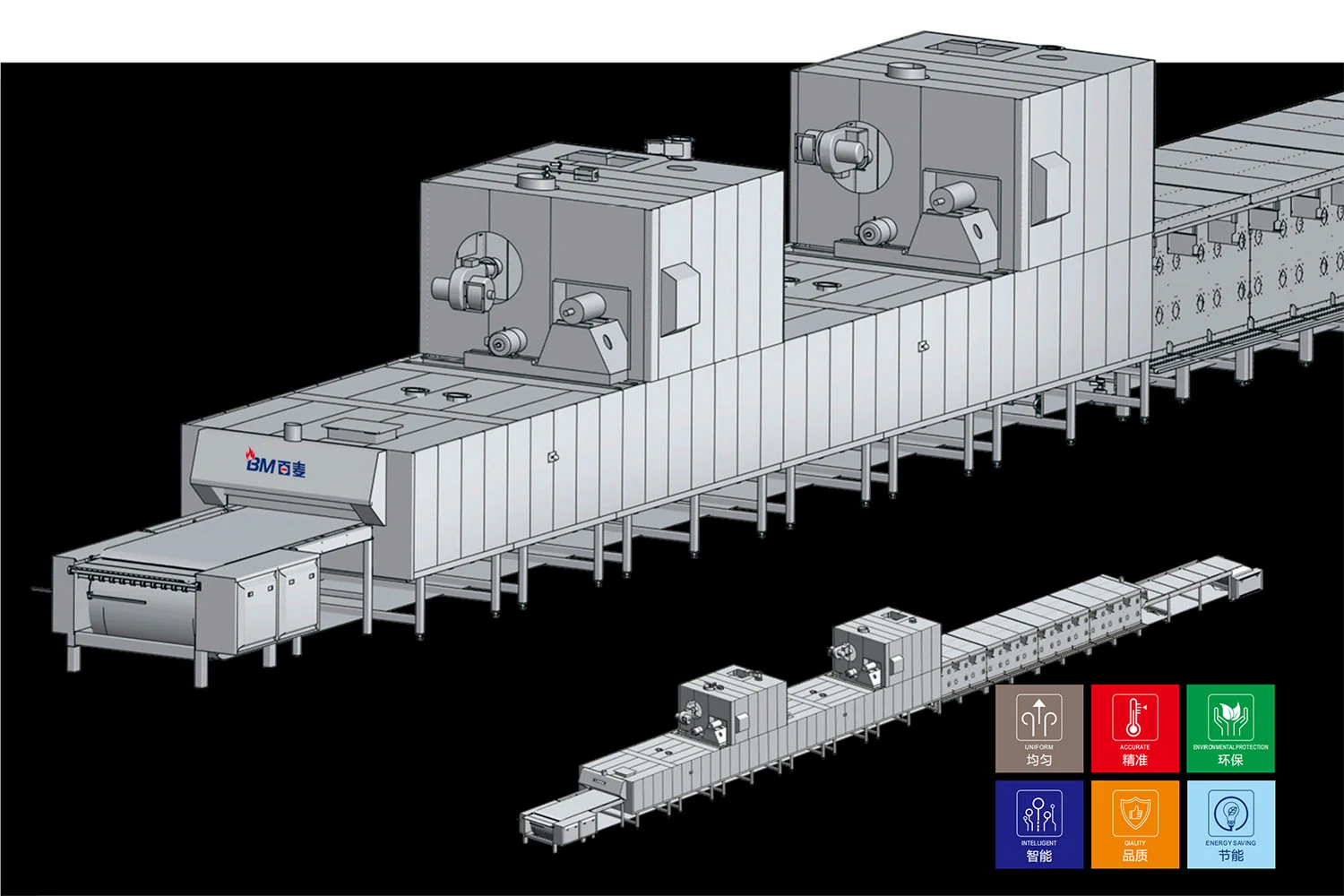

In the modern baking industry, the demand for efficient, scalable, and uniform heat treatment solutions has driven the evolution of various oven technologies. Among them, heat radiation industrial tunnel ovens stand out as a preferred choice for high-volume, continuous baking operations. These ovens are engineered to optimize thermal transfer using radiant heat mechanisms, and they are characterized by their precision, consistency, and integration potential with automated production lines. In this blog post, Baimai will share the characteristics, technical architecture, and performance indicators of heat radiation industrial tunnel ovens for sale.

1. Principle of Radiant Heat Transfer in Tunnel Ovens

At the core of heat radiation tunnel ovens is the principle of radiant heat transfer. Unlike convection ovens, which rely primarily on circulating hot air, radiant ovens transfer energy through electromagnetic waves, predominantly in the infrared spectrum. These waves directly heat the surface of the baking product without significantly heating the intervening air. This allows for a faster and more efficient heat transfer, especially for products requiring surface coloration, crust development, or precise browning profiles.

In tunnel ovens, radiant heat is typically generated by electrical elements or gas-fired radiators installed along the ceiling, walls, and sometimes the base of the baking chamber. The emitted infrared radiation penetrates a short distance into the dough, causing rapid surface heating while allowing moisture retention in the interior, which is crucial for products like crusty bread or specialty cookies.

2. Structural Composition and Thermal Zones

Industrial heat radiation tunnel ovens are long, enclosed structures, generally ranging from 10 to 50 meters in length, depending on production requirements. These ovens are divided into multiple thermal zones, each independently controlled for temperature, airflow, and radiant intensity. A typical configuration may include:

– Preheat Zone: Initiates product warming with gentle radiant energy.

– Baking Zone: Applies intense, focused radiation for core baking and crust formation.

– Coloring/Finishing Zone: Fine-tunes the surface appearance through high-emissivity radiant panels.

– Cooling Zone (optional): Gradual cooling through ambient or forced air.

The zone-based architecture allows for tailoring of the heat profile to the baking curve of different products, ensuring optimal texture, color, and moisture distribution.

3. Conveyor and Material Handling System

A defining characteristic of tunnel ovens is the continuous conveyor system that transports the product through the oven tunnel. Conveyor belts are typically made of heat-resistant stainless steel mesh, chain-linked slats, or composite materials such as Teflon-coated fiberglass, chosen based on product type and baking temperature.

The belt speed is adjustable and synchronized with the heat zones to control dwell time, which is critical for consistent product quality. High-precision servo or variable-frequency drive (VFD) motors ensure that conveyor speed remains stable under varying load conditions, enabling tight process control.

4. Energy Efficiency and Thermal Control

Radiant heat tunnel ovens offer superior energy efficiency compared to convection-based counterparts. Since radiant heat directly targets the product, less energy is wasted in heating the surrounding air. Advanced models integrate insulation systems composed of ceramic fiber or mineral wool, significantly reducing thermal losses.

Temperature control is achieved through programmable logic controllers (PLCs) linked to thermocouples and pyrometers strategically placed throughout the oven zones. These sensors provide real-time feedback, enabling fine-grained adjustments to radiant element output. Gas-fired ovens may include modulating burners with automatic air-fuel ratio control, maximizing combustion efficiency and minimizing emissions.

5. Baking Uniformity and Product Quality

One of the primary advantages of heat radiation tunnel ovens is the high degree of baking uniformity they offer. The symmetrical arrangement of radiant elements ensures even heat distribution across the belt width and along the length of the tunnel. This results in minimal product variability, a key requirement for industrial-scale production of items like bread rolls, pizza bases, biscuits, and crackers.

To further enhance uniformity, some ovens incorporate auxiliary convection systems that agitate the boundary layer of air around the product, improving heat penetration. This hybrid radiant-convection approach is particularly effective for dense or multi-layered products.

6. Automation and Integration Capabilities

Heat radiation tunnel ovens are designed for seamless integration into fully automated bakery lines. They can be connected to upstream dough processing equipment (dividers, rounders, proofers) and downstream units (coolers, slicers, packaging machines). Modern ovens feature centralized human-machine interfaces (HMIs) for control and diagnostics, allowing operators to monitor parameters such as zone temperatures, belt speed, product temperature, and oven load in real-time.

7. Maintenance and Safety Considerations

Given the high operating temperatures and continuous use, industrial tunnel ovens are built for durability and ease of maintenance. Access panels, retractable conveyor belts, and self-cleaning burners simplify inspection and servicing tasks. Safety features include over-temperature protection, gas leak detection, flame failure alarms, and emergency shutdown systems to ensure operator safety.

Routine maintenance of radiating elements, insulation integrity checks, and calibration of sensors are essential to sustain performance and prolong equipment life.

Conclusion

Heat radiation industrial tunnel ovens are indispensable in high-throughput baking operations, combining energy efficiency, uniformity, and automation to deliver consistent product quality at scale. Their ability to precisely control surface and core baking characteristics makes them ideal for a wide range of baked goods. As the baking industry continues to evolve toward greater sustainability and digitization, the design and functionality of these ovens will continue to advance, reinforcing their central role in modern food manufacturing.

Let me know if you'd like this tailored to a specific audience, like bakery engineers or commercial bakery operators.

http://www.bmbaking.com

Baimai -

AuthorPosts

- You must be logged in to reply to this topic.