- This topic is empty.

-

AuthorPosts

-

2025-01-20 at 3:29 pm #5789

Tantalum U tube lined heat exchangers have emerged as a revolutionary solution for industries requiring exceptional performance in aggressive chemical environments. Combining the unique properties of tantalum with the versatile U tube design, these heat exchangers offer unparalleled resistance to corrosion, superior thermal performance, and long-term reliability. This article Qiwei delves deep into the benefits of Tantalum U tube lined heat exchangers, explaining why they are the preferred choice for demanding industrial processes.

What Is a Tantalum U Tube Lined Heat Exchanger?

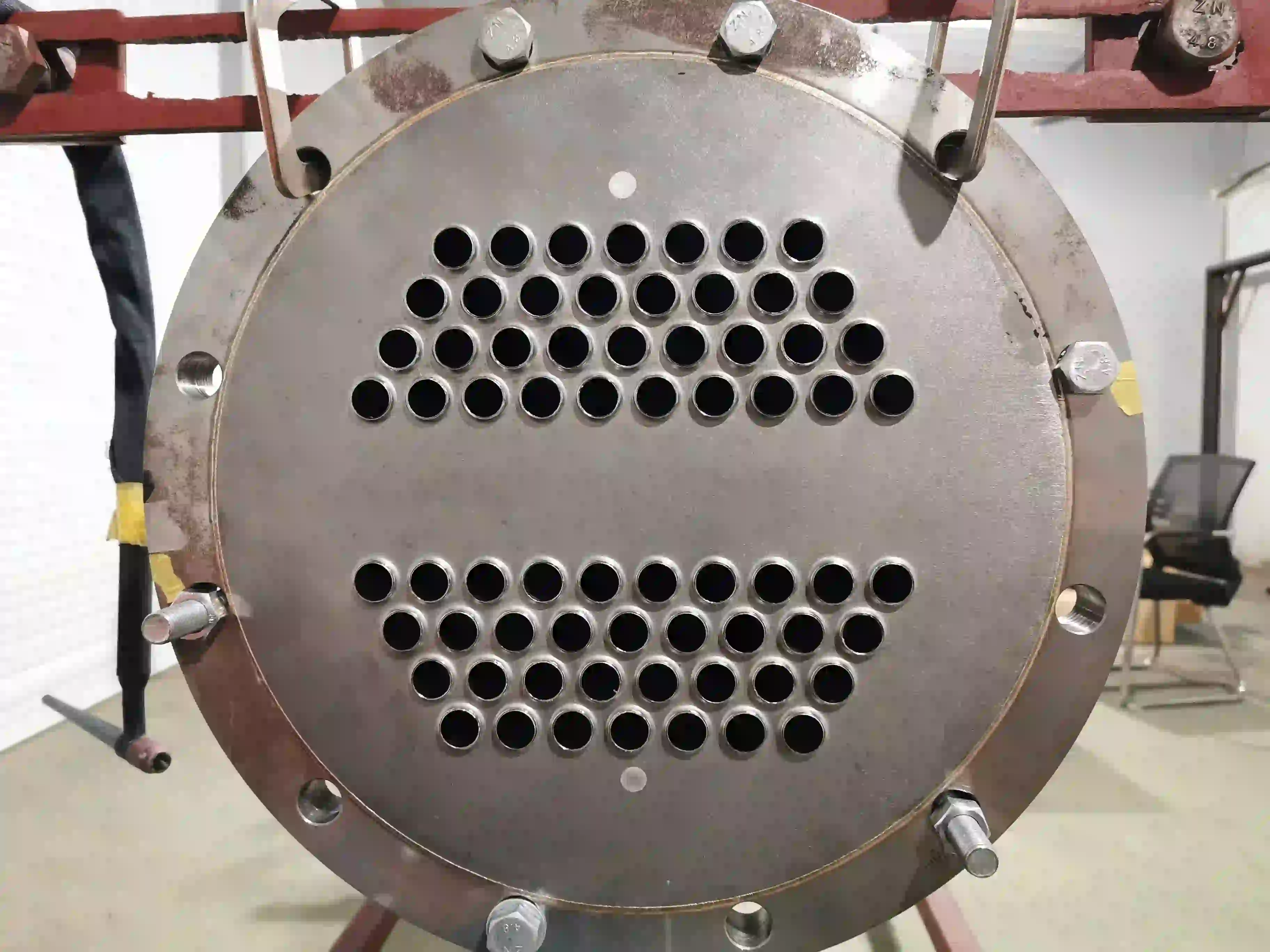

A Tantalum U tube lined heat exchanger consists of a shell-and-tube structure where the tubes are lined with tantalum. The U tube design allows the tubes to be bent into a U-shape, which accommodates thermal expansion and facilitates maintenance. The lining of the tubes with tantalum ensures excellent corrosion resistance, especially in processes involving highly acidic or aggressive fluids. This design helps to mitigate the wear and tear caused by corrosive substances that would otherwise damage conventional heat exchangers. Additionally, the use of tantalum in the lining significantly enhances the lifespan of the heat exchanger, providing long-term value for industries dealing with challenging fluid systems.

Benefits of Tantalum U Tube Lined Heat Exchangers

Tantalum U tube lined heat exchangers are widely regarded as the ultimate solution for extreme operating conditions. Their benefits extend beyond corrosion resistance, making them a superior alternative to traditional heat exchanger materials.

1. Exceptional Corrosion Resistance

Tantalum's primary advantage lies in its ability to resist corrosion in a wide range of aggressive environments. Unlike stainless steel or titanium, tantalum is nearly inert to strong acids such as hydrochloric acid (HCl), sulfuric acid (H2SO4), and even aqua regia. This makes it the ideal material for heat exchangers operating in highly corrosive processes. For instance, in chemical plants, where fluids with low pH levels are commonly encountered, the lining ensures that the equipment remains unaffected by the acidic environment. This resistance significantly reduces the risk of failure, preventing costly downtime and safety hazards.

2. High Temperature and Pressure Tolerance

The performance of many heat exchangers is limited by the material's inability to withstand extreme temperatures and pressures. Tantalum maintains its structural integrity even under intense thermal and mechanical stress. Its melting point of 3017°C ensures that it can perform in high-temperature applications without deforming or losing its protective properties. This makes Tantalum U tube lined heat exchangers particularly valuable in industries like petrochemical refining, where temperatures and pressures frequently fluctuate during processes such as catalytic cracking or distillation.

3. Superior Thermal Conductivity

Tantalum has excellent thermal conductivity, allowing heat to transfer efficiently between fluids. In a heat exchanger, efficient thermal transfer is critical for reducing energy consumption and ensuring consistent process performance. The use of tantalum as a lining material enhances the heat exchanger's overall thermal performance without compromising its resistance to corrosion. This benefit is particularly useful in high-throughput industries, where rapid and consistent heat exchange is essential for maintaining production efficiency.

4. Reduced Maintenance and Downtime

Maintenance and repairs often account for a significant portion of operating costs in industries that use heat exchangers. Thanks to the durability and corrosion resistance of tantalum, Tantalum U tube lined heat exchangers require far less frequent maintenance compared to their counterparts made from traditional materials. This durability translates to fewer disruptions, lower repair costs, and improved operational reliability.

5. Extended Service Life

Tantalum U tube lined heat exchangers are built to last. Their ability to withstand corrosive fluids, high temperatures, and mechanical stress ensures a significantly longer service life than conventional heat exchangers. Over time, this durability leads to a reduced total cost of ownership, making them a cost-effective investment for industries requiring high-performance equipment.

Tantalum U tube lined heat exchangers are a technological marvel, offering unparalleled corrosion resistance, thermal efficiency, and long-term reliability. From chemical processing to power generation, these heat exchangers have proven their value in some of the most demanding industrial environments. By investing in Tantalum U tube lined heat exchangers, companies can achieve greater efficiency, reduced downtime, and long-term cost savings, making them an indispensable tool for modern industries.

https://www.tnztn.com/Tantalum-U-tube-Heat-Exchanger-Lining.html

http://www.tnztn.com

Wuxi Qiwei Nonferrous Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.